blown film machine pdf

Output Screw LD Ratio wInverter HDPELDPE. Blown films provide a better balance of properties between the machine and transverse directions.

SINGLE PLATFORM MONO LAYER BLOWN FILM MACHINE Main Motor Model Suitable Material Screw Dia.

. Groove Feed Barrel and cooling jacket available. 5 Layer Blown Film Co-ex Line Highly versatile die design leading to optimum quality of Barrier as well as Facilitates optimisation of Tie Layer Blown Film Co-extrusion Lines In Technical. Blown film extrusion is one of the most commonly used thin gauge fabrication processes for manufacturing plastic films in the world.

Blown Film Machine CE45-65TT CE55-75TT Features. The delivery of high melt quality is a. Film Extrusion An Overview Sciencedirect Topics Extrusion and.

Given therefore a single screw machine is being described that has a screw of diameter 60 mm and a length of 24 screw diameters that is a LD ratio of 241. 08 28 mm Bubble diameter BUR blow up ratio. 600 4000mm Die diameter.

PDF On Dec 19 2012 John Vlachopoulos and others published Blown Film Dies Find read and cite all the research you need on ResearchGate. The blown film extrusion process can produce. Implementing Blown High Density Film Technology Before and during installation Gloucester specialists not only apply their extensive highly practical knowledge of blown HD film to your.

6 250 microns Layflat width. Motorized openclose updown Bubble Cage. WH blown film lines are designed especially for the flexible packaging industry.

Machine Construction A cut. 100 600mm Die gap. We are producing blown film lines since 1967 and have consistently set new standards such as the.

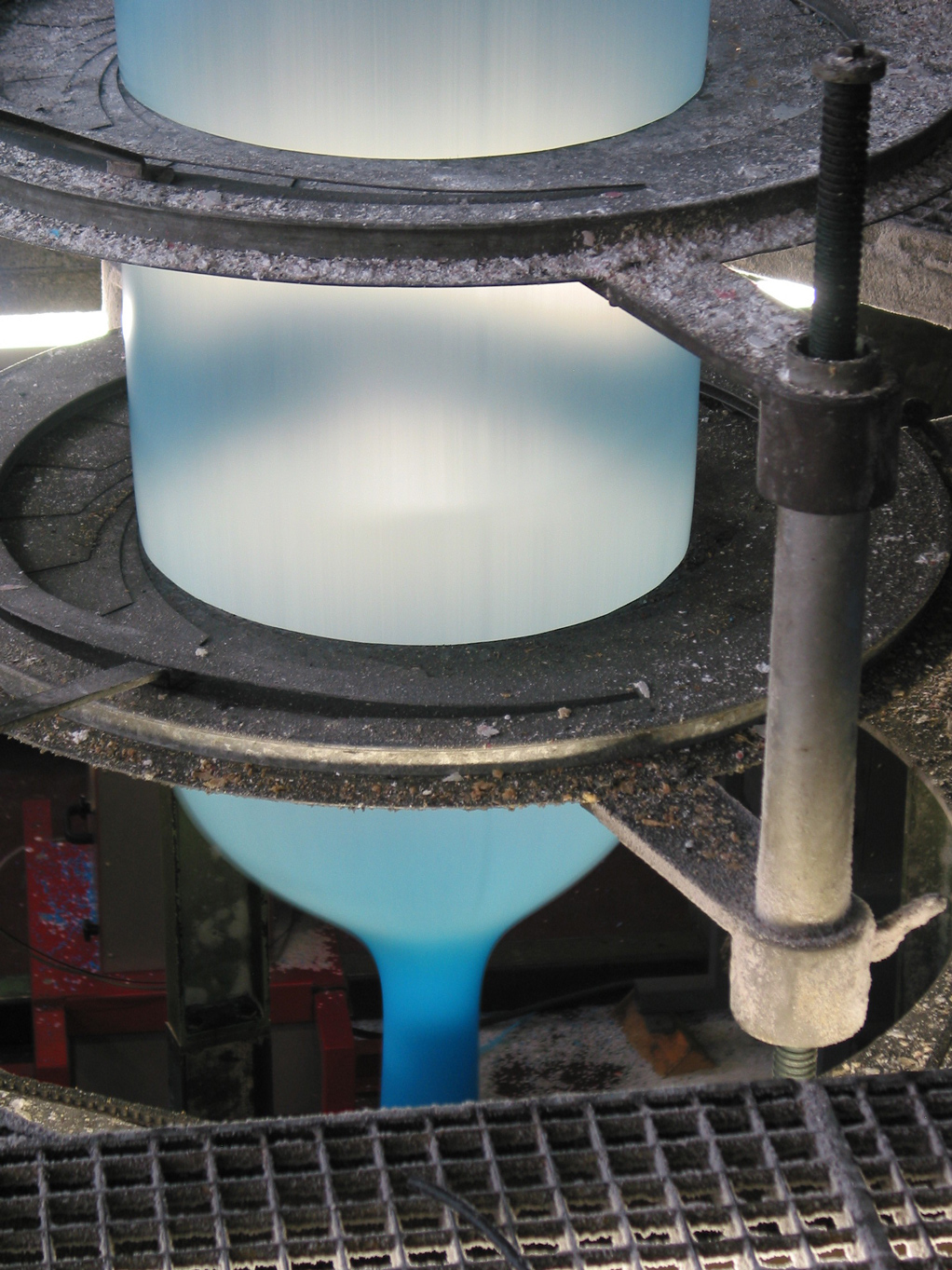

Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5. Working of Blown Film Extrusion Machine. The blown film process can produce a wide range of film sizes from the same die.

Manual screen changer. SmartFlex Blown Film lines 1 3 and 5 layers characterized by a competitive investment level maximized flexibility for different applications. 51 Introduction to Blown Film Extrusion.

Blown film lines are used to make shrink wrap films. Elements of blown film Film thicness. Machine Direction Asymmetrical MD Wrinkle Processing Conditions Asymmetrical MD Wrinkles TD gauge variation insufficient web tension between idler rollers Equipment insufficient.

The machines are superior in. 5 layers Non Barrier Blown Film Machine Product Application Introduction non barrier film launched hy high intelligent with great production performance. The purpose of the blown film die is to receive polymer melt from the extruder and deliver it to the die exit as a thin annular tubular film.

Bandera Blown Film extrusion range includes. Blown Film Troubleshooting Guide Bubble Instability Chatter Die Lines Poor Heat Seal Melt Fracture Gauge V ariation cont Gels Causess Possible Solutions Dirty Air Ring Cont.

Blown Film المعهد العالي للصناعات البلاستيكية المعهد العالي للصناعات البلاستيكية

1 Schematic Of The Film Blowing Process Download Scientific Diagram

Plastar Blown Film Machine Manufacturer

Single Screw Extrusion An Overview Sciencedirect Topics

Sheet Extrusion Lines Meaf Machines B V

Plastics Extrusion Presses Worksafe

Products Bandera Plastics Extrusion Italy

Extrusion Supervisor Resume Samples Qwikresume

Pdf Extrusion The Definitive Processing Guide And Handbook Luis Munoz Academia Edu

Pdf Understanding Rheology And Technology Of Polymer Extrusion First Edition

Blown Film An Overview Sciencedirect Topics

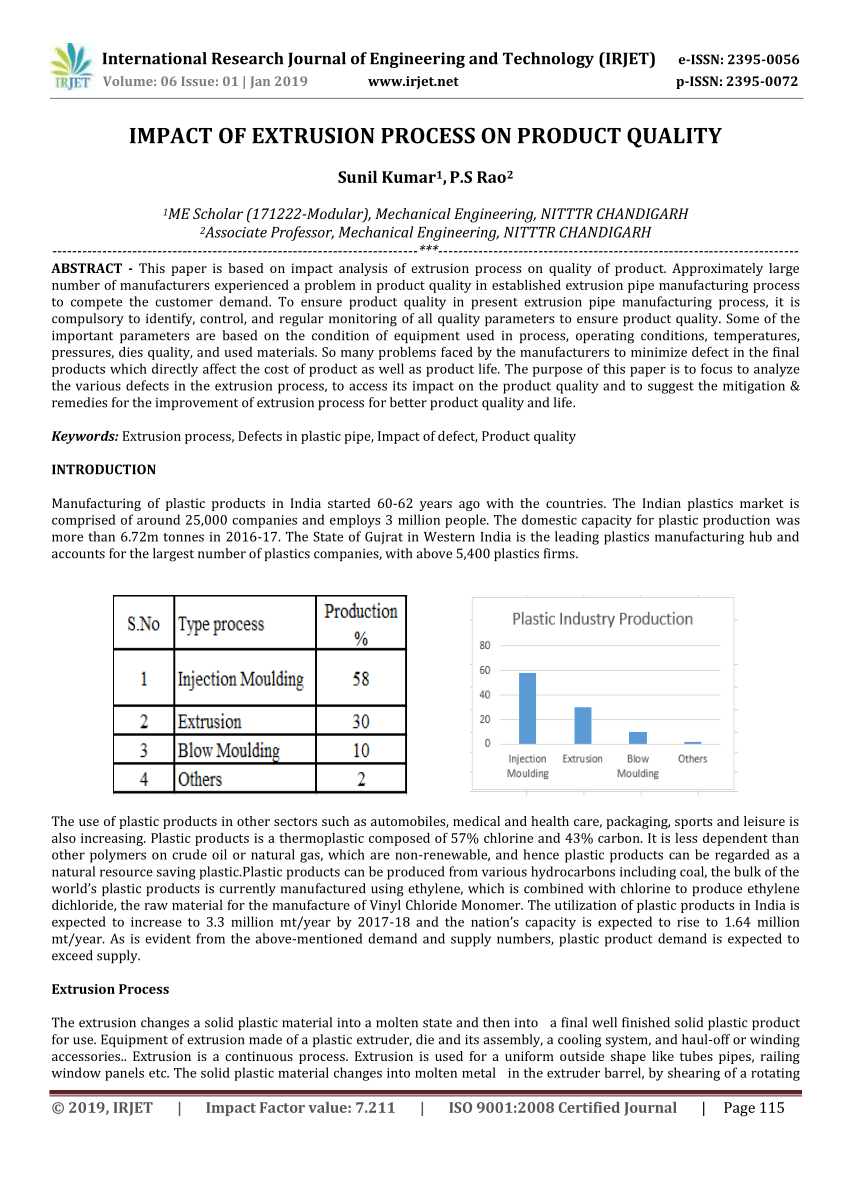

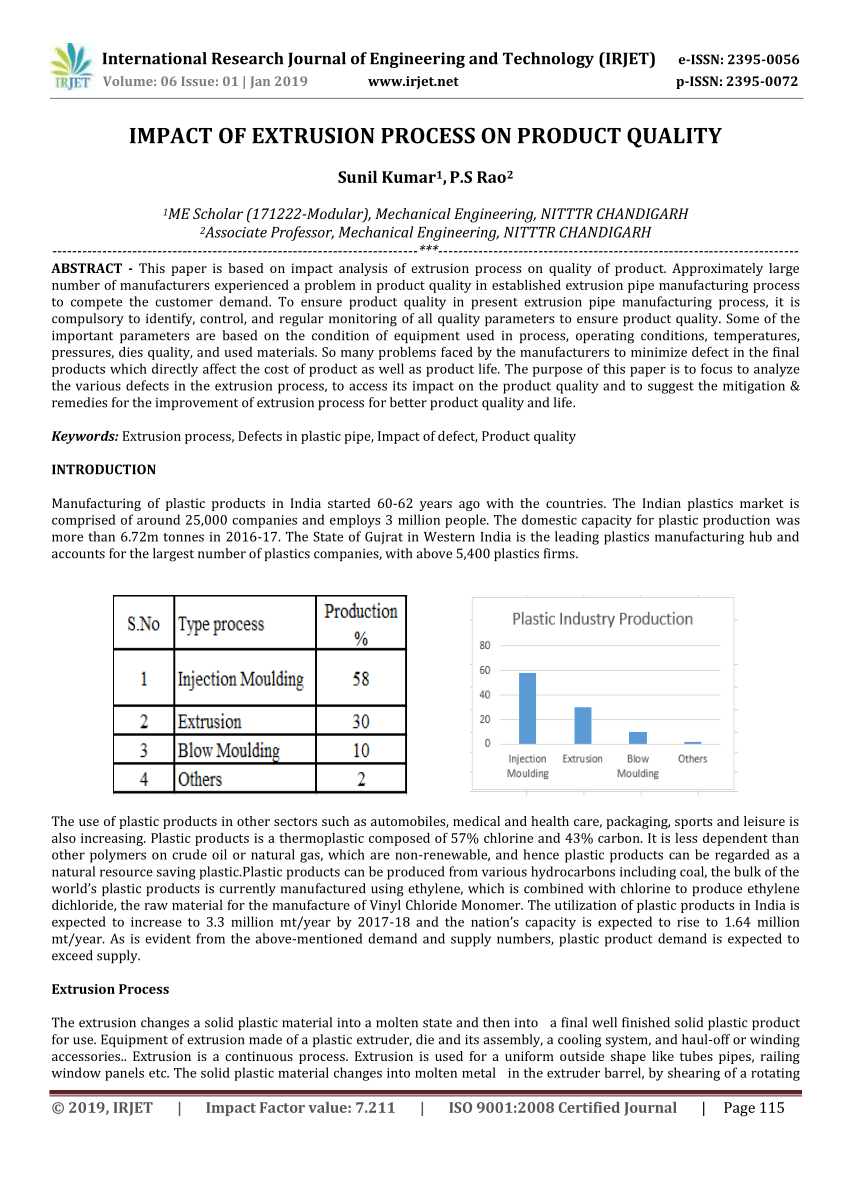

Pdf Impact Of Extrusion Process On Product Quality

Film Blowing Machine Wikipedia

Pdf Report About Blown Film Extrusion Production Processes At Luuka Plastics Limited Peter Semata Academia Edu

All Windsor Machines Limited Catalogs And Technical Brochures

Blown Film Extrusion Blown Film Extrusion Process Blown Film Extruders Manufacturers Suppliers Exporters